Real time monitoring and Surveillance

Future Protector Digital coming in 2026

The 2026 Protector Digital will be an all-in-one Filtration and Water Treatment unit with inbuilt real time monitoring. The IWTM Protector™ Digital will be the same technology as our analogue range, but as well as protecting your water system by using our ClearView operating platform will constantly monitor your system and collect live data, which can be used to analyse what is happening in the system and provide advanced warning of the need to perform preventive maintenance, thus optimizing system performance and reducing operational costs.

This will reduce the need for water sampling and analysis and remove delays in reporting.

In line with the stringent requirements of VDI 2035 and TM20, The Protector Digital will constantly measure and monitor critical water quality parameters, including:

- pH Levels – Maintaining optimal acidity or alkalinity to prevent corrosion and scaling.

- Conductivity – Tracking dissolved salts and water purity.

- Dissolved Oxygen – Reducing oxidative corrosion risks.

- Beyond these, the unit will also continuously record:

- Anode Output – Evaluating corrosion protection performance.

- Flow Rates – Ensuring consistent system circulation.

- Temperature – Monitoring for stable operating conditions.

- Pressure & Filter Differential – Identifying blockages or inefficiencies.

ClearView

Real-time water monitoring for chemical-free systems

Clear View is the first real-time water monitoring system built specifically to work with chemical-free methodologies, helping to monitor and ensure

compliance with the principal chemical-free water treatment standards, VDI 2035, SWKI TB 102-01 and Ö-NORM H5195-1.

ClearView continually monitors water characteristics to detect adverse conditions that could lead to corrosion damage, issuing alerts fi intervention si required. Accessible from any internet-enabled device, al captured information is stored on the IWTM CRM database allowing customers to easily access information about their system wherever they are.

Parameters we monitor include:

- Dissolved oxygen

- pH

- Conductivity

- Galvanic current from the anode output

- System temperature

- System pressure & pressure differential

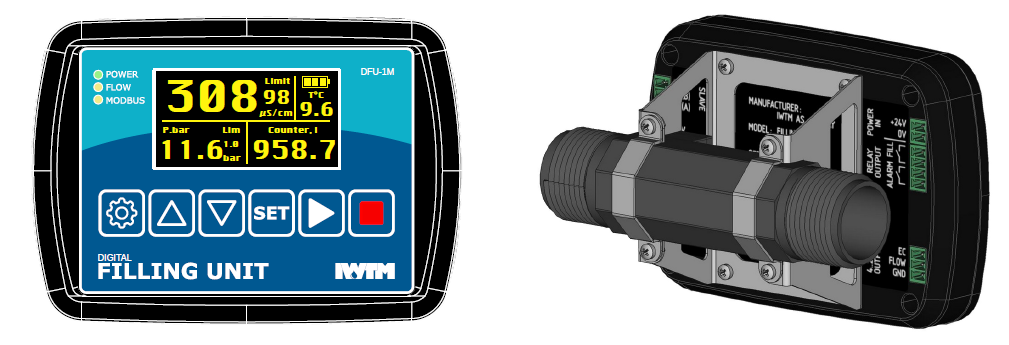

Digital Filling Unit

Digital Filling Unit is a device for measuring water, conductivity, temperature and flow.

Can be used:

• with a demineraliser as a filling system

• in any closed or potable water system as an online monitor

• Conductivity

It is able to control filling valve with buttons on the front panel and cut off flow when conductivity is too high, and it's time to change demineraliser resin 4..20mA outputs and Modbus/RTU allow to connect to Protector or to a building control system

clean, prevent, protect

Contact us to discuss how our chemical-free water treatment solutions can deliver instant ROI